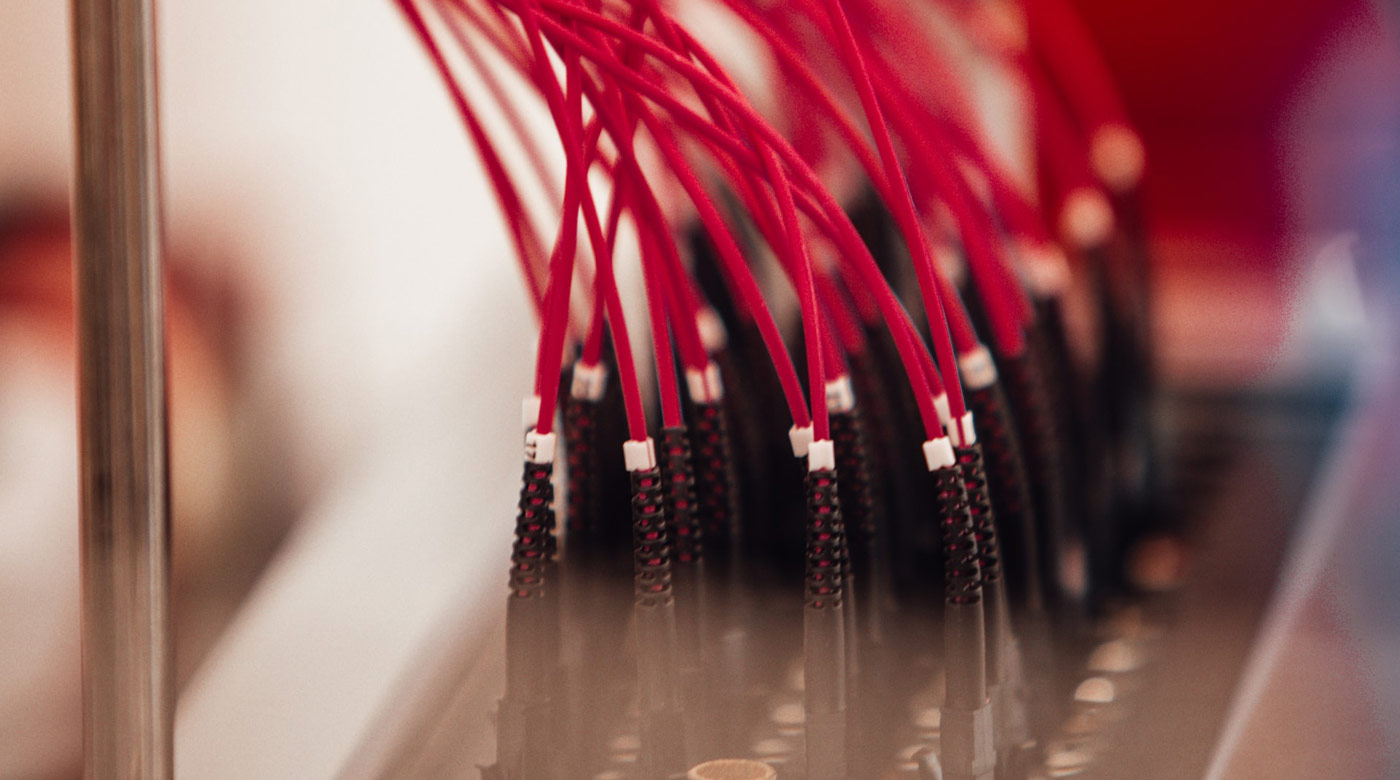

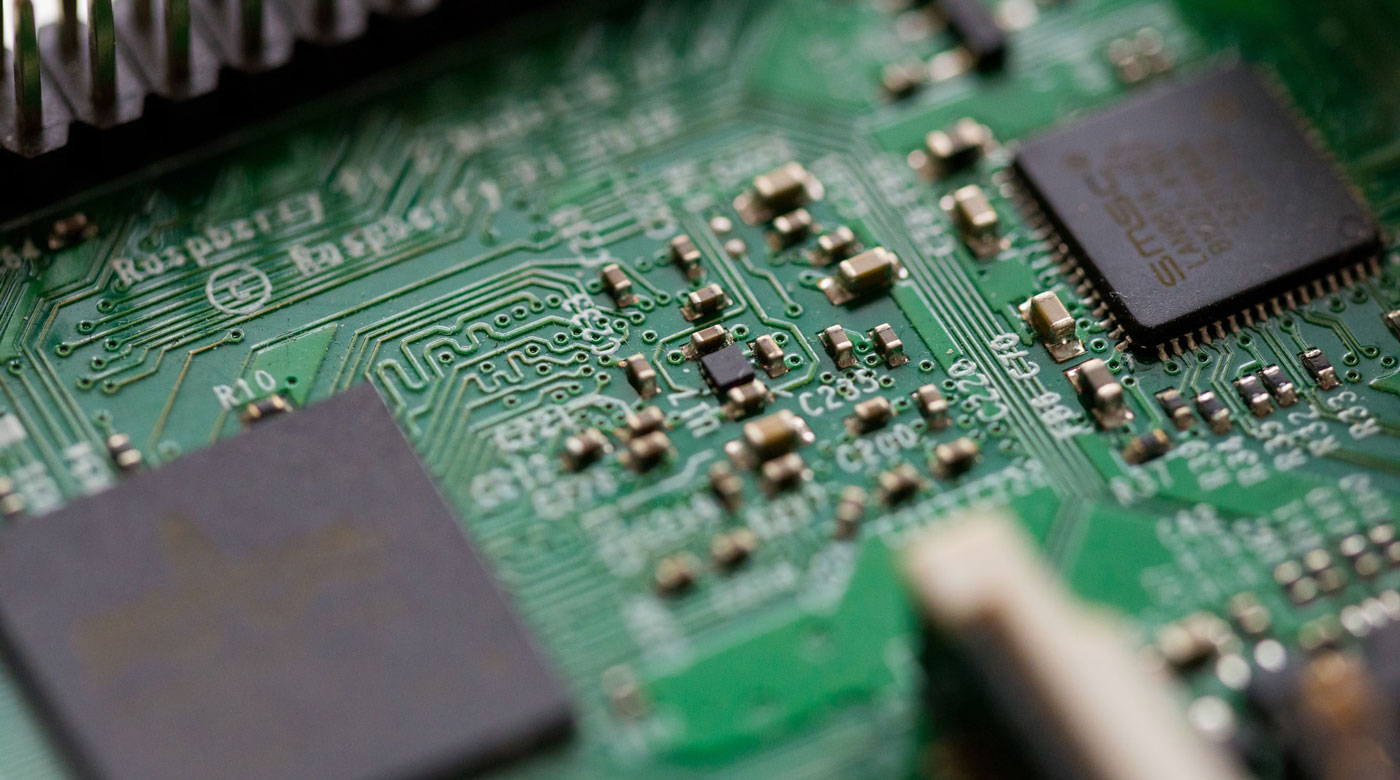

Located in the global manufacturing hub of Suzhou Industrial Park HANZA China caters to an international customer base. We offer flexible manufacturing capabilities for industrial and consumer needs. Our 80 professionals have long experience from wire and cable processing to complex project-based panel and cabinet assemblies. To further expand our scope and service level we moved to new, bigger facilities during 2021 and have added PCB assembly to our offer.

HANZA’s Cluster China provides services to meet the needs of local and global customers’ manufacturing needs. We offer full supply chain

Located in the global manufacturing hub of Suzhou Industrial Park our factory with a staff of 80 manufactures products used in industries from heavy

HANZA Electric Suzhou provides professional assembly services focused on wire and cable harnesses, assembly of control panels and cabinets,

With over 20 years of history for the site, our team of professionals has the experience to offer a turn-key solution to most customer needs.

All HANZA factories hold a variety of certifications adapted to the business and technology in which they operate. The certificates complement our ambitious protocols for reduced environmental impact, data security, work environment and product quality.

ISO 14001

ISO 9001

UL file No. E251348

Switch number

Tel. +86-512-62868001

Address

HANZA Electric Suzhou

Dongfang Industrial Park

Area B, Building 1, 3rd Floor

No. 20 Huayun Road

Suzhou Industrial Park

Jiangsu province, China

Cluster President

Rainer Olesk

+86-1370 14 19 301

moc.aznah@kselo.reniar

Account Manager

Fanny Lu

moc.aznah@ul.ynnaf

Account Manager

Lynne Wu

moc.aznah@uw.ennyl