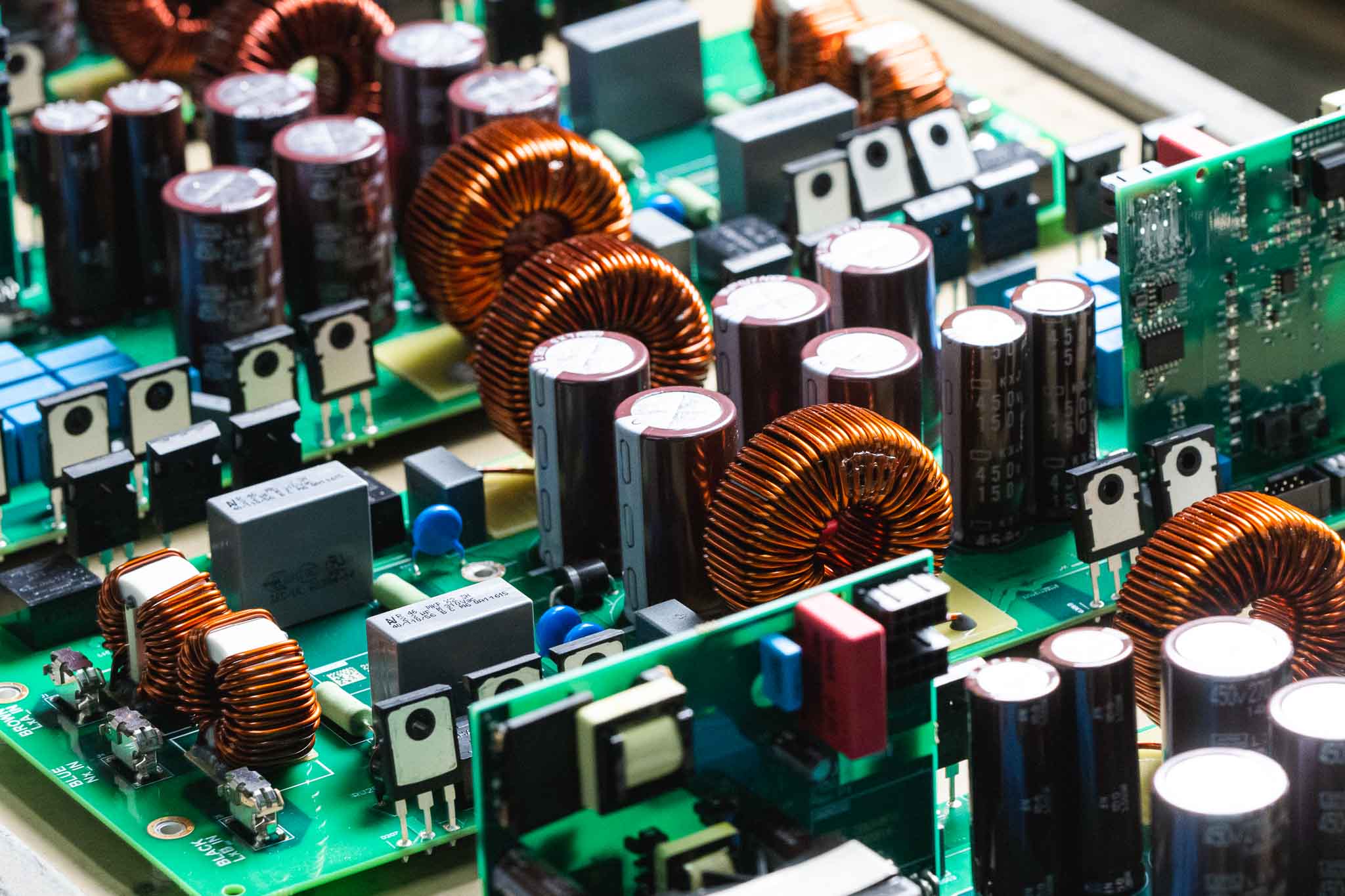

At HANZA Electronics Prabuty we provide complete electronics manufacturing services with commitment to high quality, competitive cost, and professional customer service. We offer box-build, test development, automation and logistic solutions to world-leading customers. We are a part of HANZA Group which have operations in 7 countries across Europe and China.

We offer complex manufacturing, supply chain, logistics, purchasing and procurement, system integration and other services based on our customer’s demand. HANZA Electronics Prabuty are certified according to ISO 9001 and ISO 14001.

In Prabuty we have over 200 dedicated and skilled colleagues. Thanks to our location in the heart of Europe, we can offer manufacturing solutions close to the rest of Europe, mainly Scandinavia and the DACH countries (Germany Austria and Switzerland).

We provide full technical support for our production processes. Together with the customer, we ensure that the product is designed in a way that allows it to be produced in the most cost-efficient way while also assuring great quality.

We know that reliability and cost are two of the most important factors for our customers. Therefore, we ensure that our daily work follows these guidelines, which gives our customers more time to develop their offering and strengthen their core business.

All HANZA factories hold a variety of certifications adapted to the business and technology in which they operate. The certificates complement our ambitious protocols for reduced environmental impact, data security, work environment and product quality.

ISO 9001 • ISO 14001

Switch number

+48 55 262 44 80

Address

HANZA Electronics Prabuty

Aleja Wojska Polskiego 18B

82-550 Prabuty

Cluster President

Pawel Filarowski

+48 603 755 288

moc.aznah@iksworalif.lewap

Operations Manager

Robert Kaźmierski

+48 885 040 406

moc.aznah@iksreimzak.trebor

Key Account Manager

Piotr Wiśniewski

+48 605 068 345

moc.aznah@iksweinsiw.rtoip

Purchasing and Planning Manager

Justyna Jankowska

+48 607 900 470

moc.aznah@akswoknaj.anytsuj

Quality Manager

Małgorzata Sokołowska

+48 607 044 550

moc.aznah@akswolokos.atazroglam

Chief Accountant

Ewa Siuda

+48 552 624 496

moc.aznah@aduis.awe