State of art factory HANZA Mechanics Tallinn provides variety of sheet metal services, assembly and system integration services for customers also with complex manufacturing needs. Our Tallinn factory includes also the largest Cut Center in the Baltics. We are also the owner of Profiline brand which is the biggest producer of drywall profiles in the region.

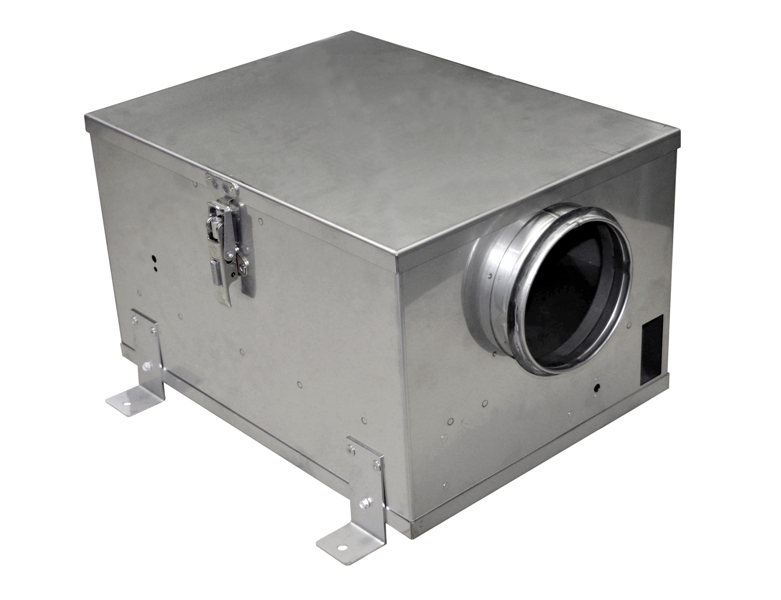

We are your partner in metal based manufacturing – managing everything from complex systems to smaller components. Manufacturing has been made easy for you.

The modern production facility in Tallinn covers an area of 16 000 square meters and employes almost 200 professionals.

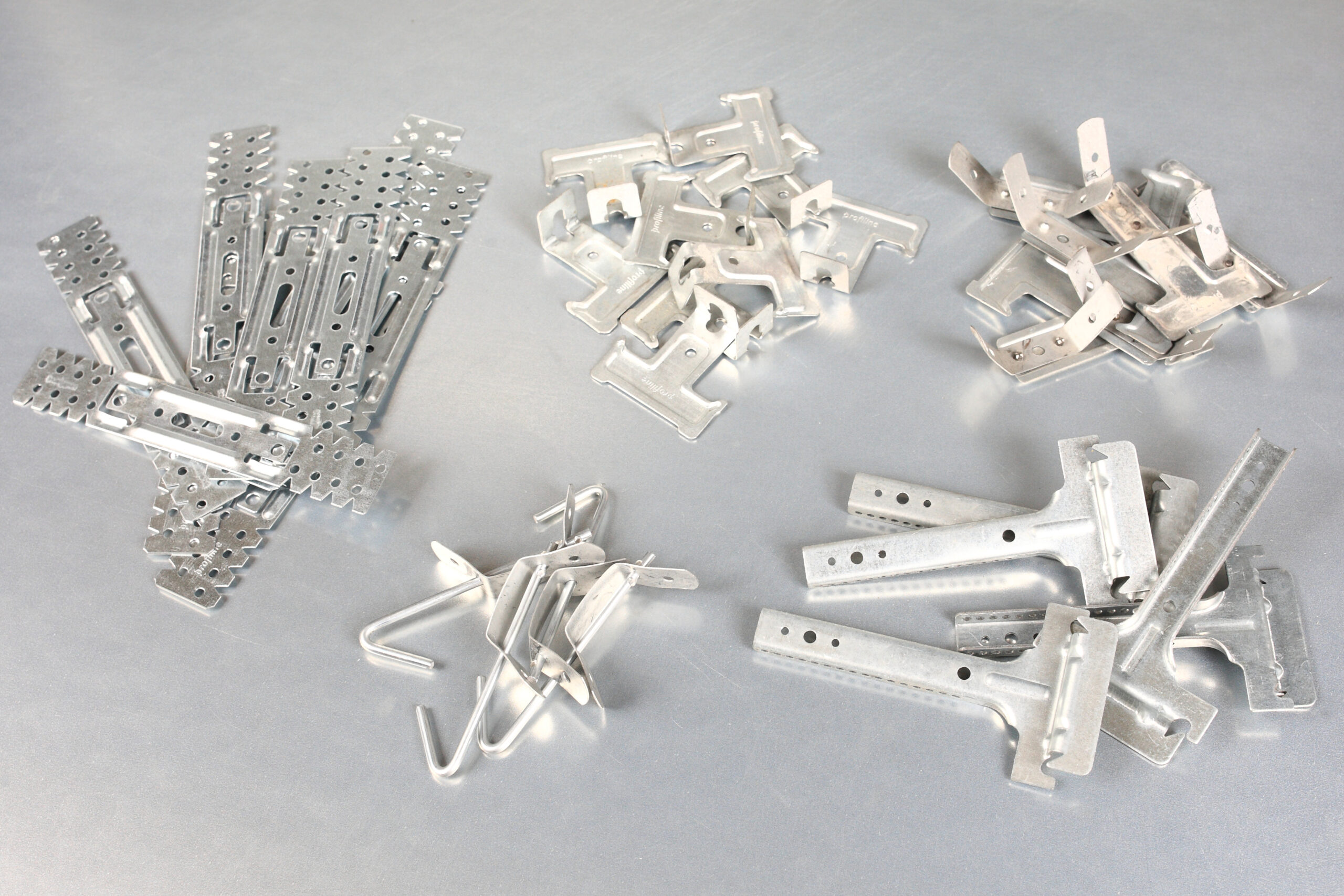

We offer a good variety of sheet metal services, assembling, welding, powder coating, bending, laser cutting. In addition we have the largest Cut Center in Baltics area and we own the brand for Profiline profiles.

Our modern production facility offers variety of services under the same roof.

All HANZA factories hold a variety of certifications adapted to the business and technology in which they operate. The certificates complement our ambitious protocols for reduced environmental impact, data security, work environment and product quality.

ISO 9001 • ISO 14001

Address

HANZA Mechanics Tallinn

Loovälja tee 11

Liivamäe küla

74207 Jõelähtme vald

Harju maakond

Estonia

moc.aznah@ATMH.sredro

Cluster President

Liivar Kongi

+372 562 426 33

moc.aznah@ignok.raviil