Energy harvesting for smart sensors

Energy harvesting for smart sensors

Some of our customers manufacture machines and plants that are exported worldwide and are in continuous operation for years. In order to avoid expensive interruptions in the operating process, we have developed solutions for continuous condition monitoring in various projects. At the same time, potential failure of a wear part should be predicted as accurately as possible before it is actually defective (predictive maintenance). In this way, repair and maintenance times can be better planned and follow-up costs minimized. For this purpose, machines must be equipped with various sensors. However, many older plants are not prepared for this – who thought two decades ago or even earlier that a cement conveyor system would one day be retrofitted with sensors for condition monitoring?

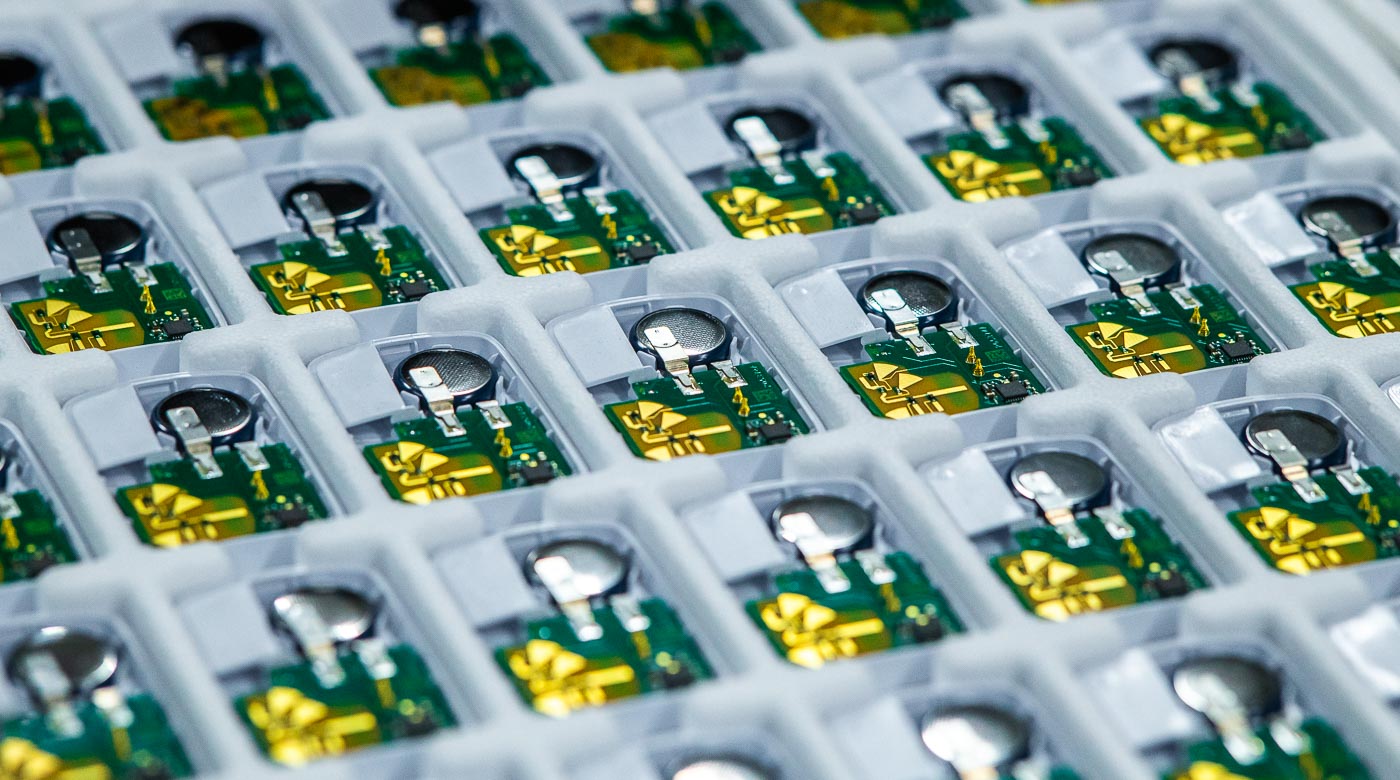

To avoid expensive installation of cables or regular replacement of batteries when retrofitting existing plants, we use energy harvesting to supply energy to intelligent sensors networked by radio. The idea of energy harvesting is to obtain energy from the environment, for example via photovoltaics or thermo- or piezoelectrically. As a rule, the amounts of energy obtained in this way are relatively small. However, if power-saving and intelligent sensors are used in the development of corresponding retrofit solutions, the amount is often sufficient.

The sensor data obtained is then processed directly on the sensor and, in the event of limit values being exceeded, passed on by radio. This can be done, for example, via Bluetooth or WLAN to a tablet or smartphone in the vicinity, or via LoRaWAN to a more distant edge gateway.