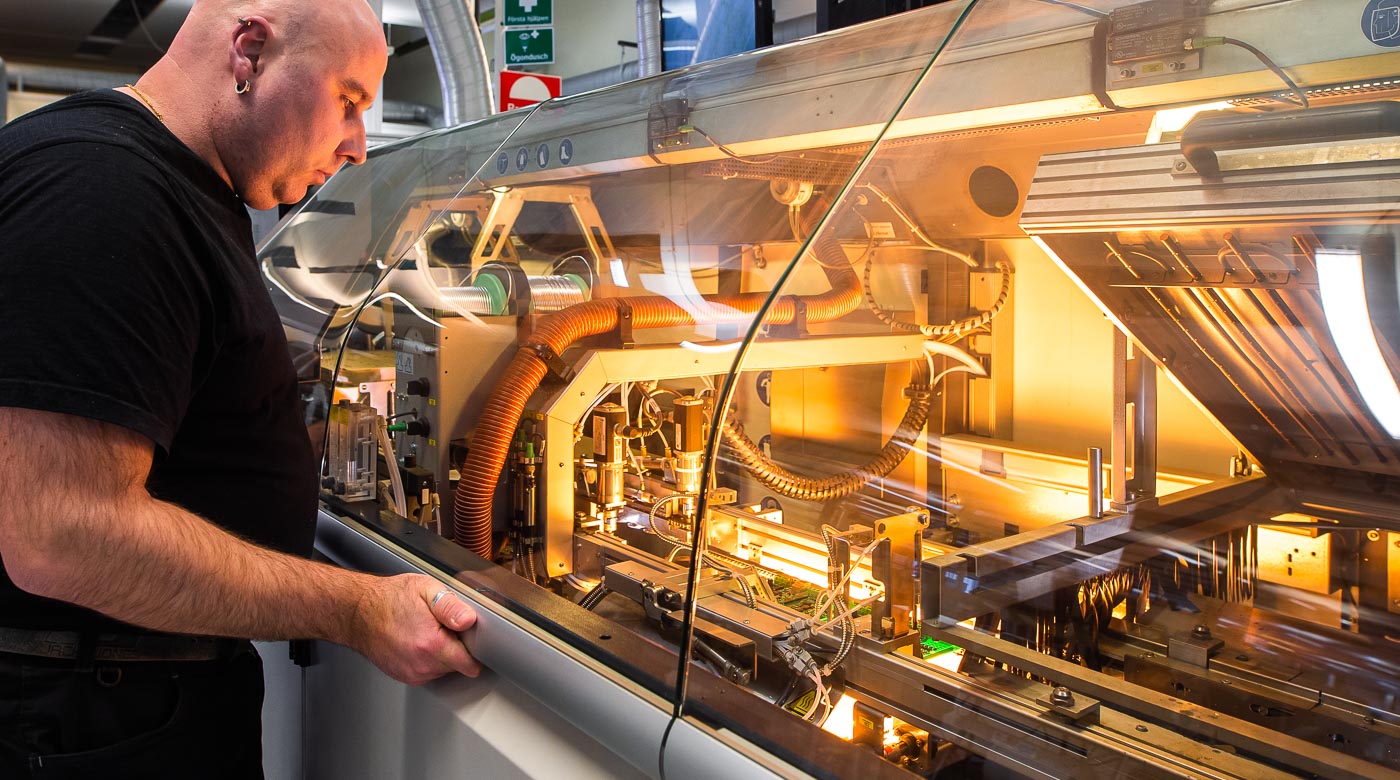

HANZA Assembly Remscheid, located in Remscheid, is a full-service provider that helps you to cost-effectively develop and manufacture products within the area of control cabinet construction or industrial electronics and EMC testing. Whether you need small batch sizes of products, collaborative development services or complex automation systems, we can handle the entire process.

Our skills in design and development include hardware and software for power electronics, heat induction technology, mechanical design,

We are located at the IDC Barmag, an industry and service center located near the historic center of Remscheid-Lennep. There you will

We carry proven competencies in a number of different development and production areas, which enable us to offer a full supply chain,

For over 25 years, HANZA Assembly Remscheid has successfully developed and manufactured electronic systems for machines and plants.

All HANZA factories hold a variety of certifications adapted to the business and technology in which they operate. The certificates complement our ambitious protocols for reduced environmental impact, data security, work environment and product quality.

ISO 9001

Address

HANZA Assembly Remscheid

Leverkuser Strasse 65,

D-42897 Remscheid

Vertrieb/Sales

Michael Hoffmann

Telefon: +49 2191-576 2429

Telefax: +49 2191-576 1671

moc.aznah@nnamffoH.leahciM

Kundenbetreuung/ Order desk

Michael Madeja

Telefon: +49 2191-576 2347

Telefax: +49 2191-576 1671

moc.aznah@ajedaM.leahciM

Kundenbetreuung/ Order desk

Jörg Roch

Telefon: +49 2191-576 2652

Telefax: +49 2191-576 1671

moc.aznah@hcoR.greoJ

Faktura / Invoice/Export

Jasmin Samulowski

Telefon: +49 2191-576 2621

Telefax: +49 2191-576 1671

moc.aznah@ikswolumaS.nimsaJ

Service

+49 2191-576 1809

moc.aznah@ecivres-diehcsmer