Our second factory within sheet metal processing and assembly in Cluster Sweden is situated in Svanskog approx. 40 km from the larger sister company HANZA Mechanics Töcksfors. We offer processing of small, large, and advanced articles with a high degree of automation and flexibility combined. This makes us competitive in both low and high-volume manufacturing.

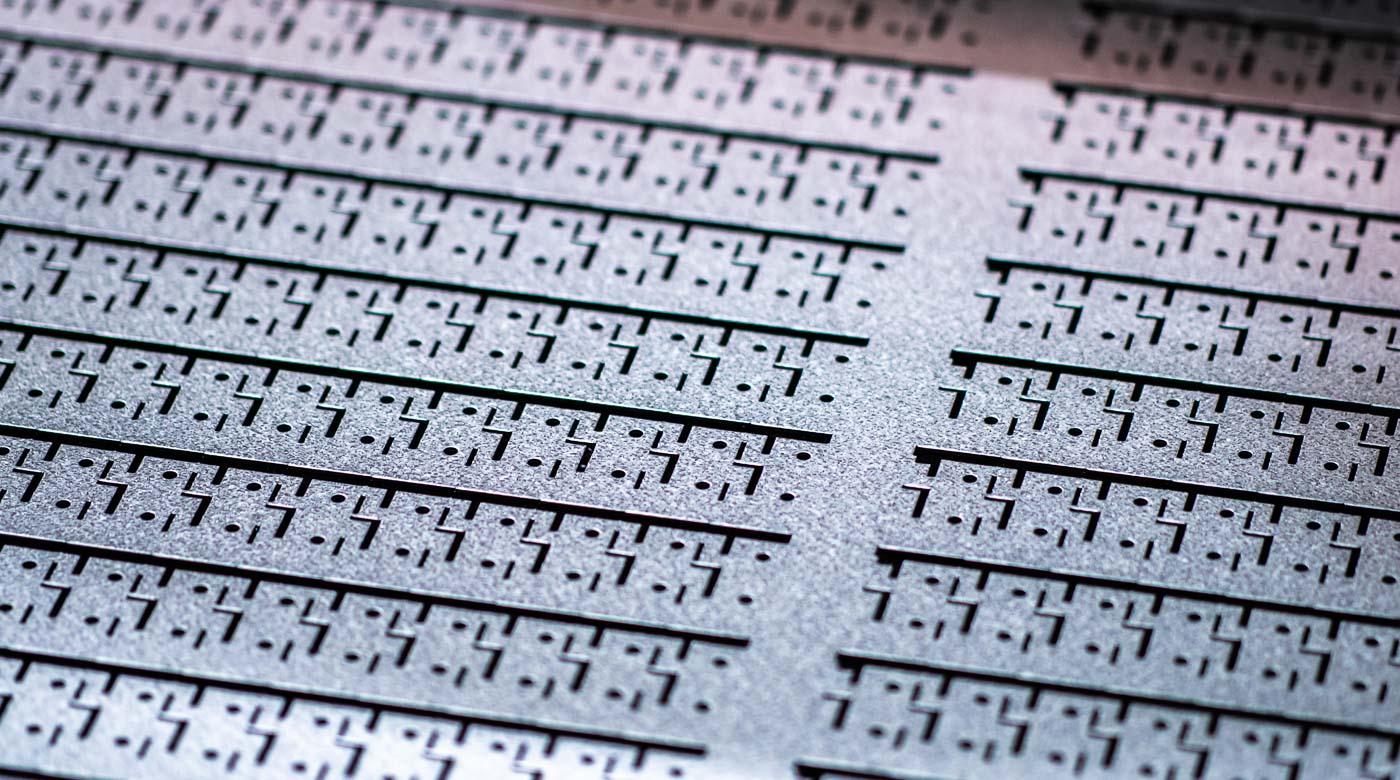

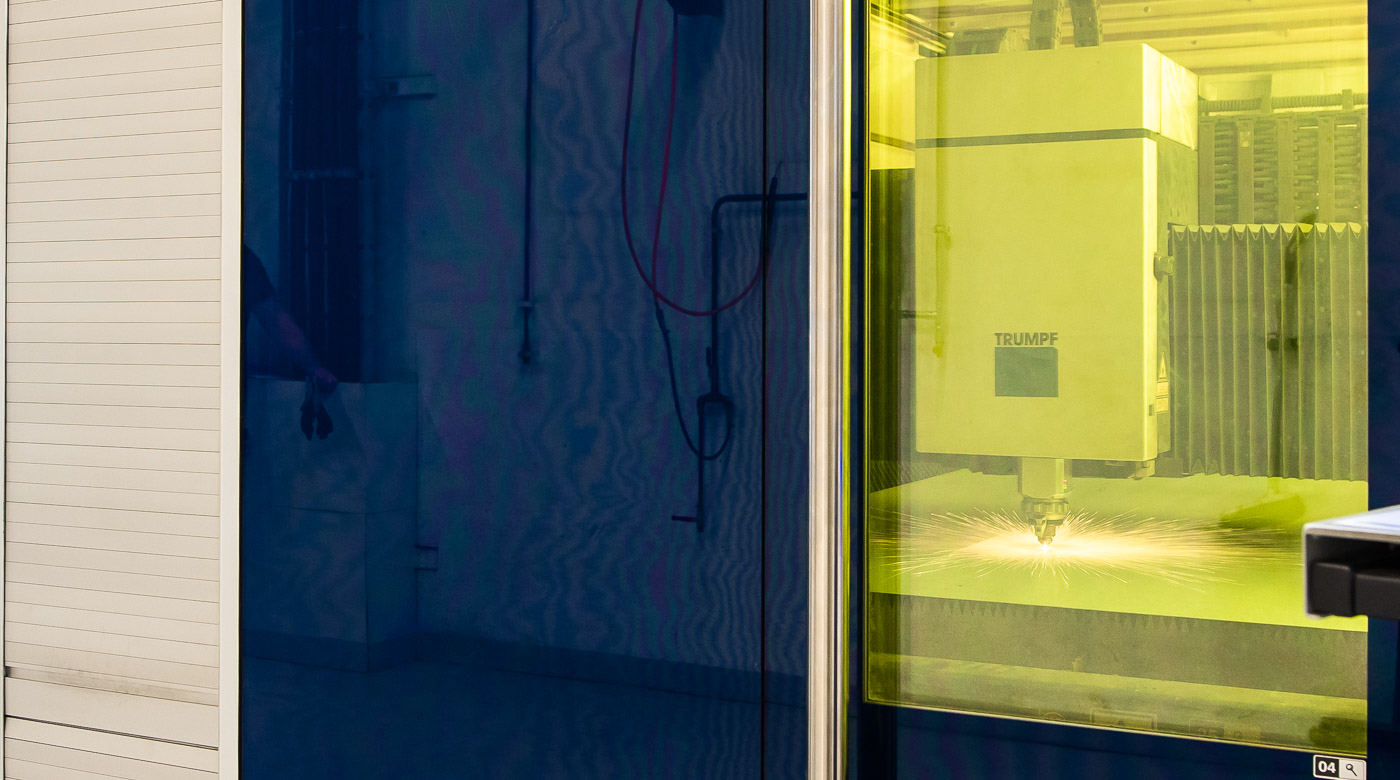

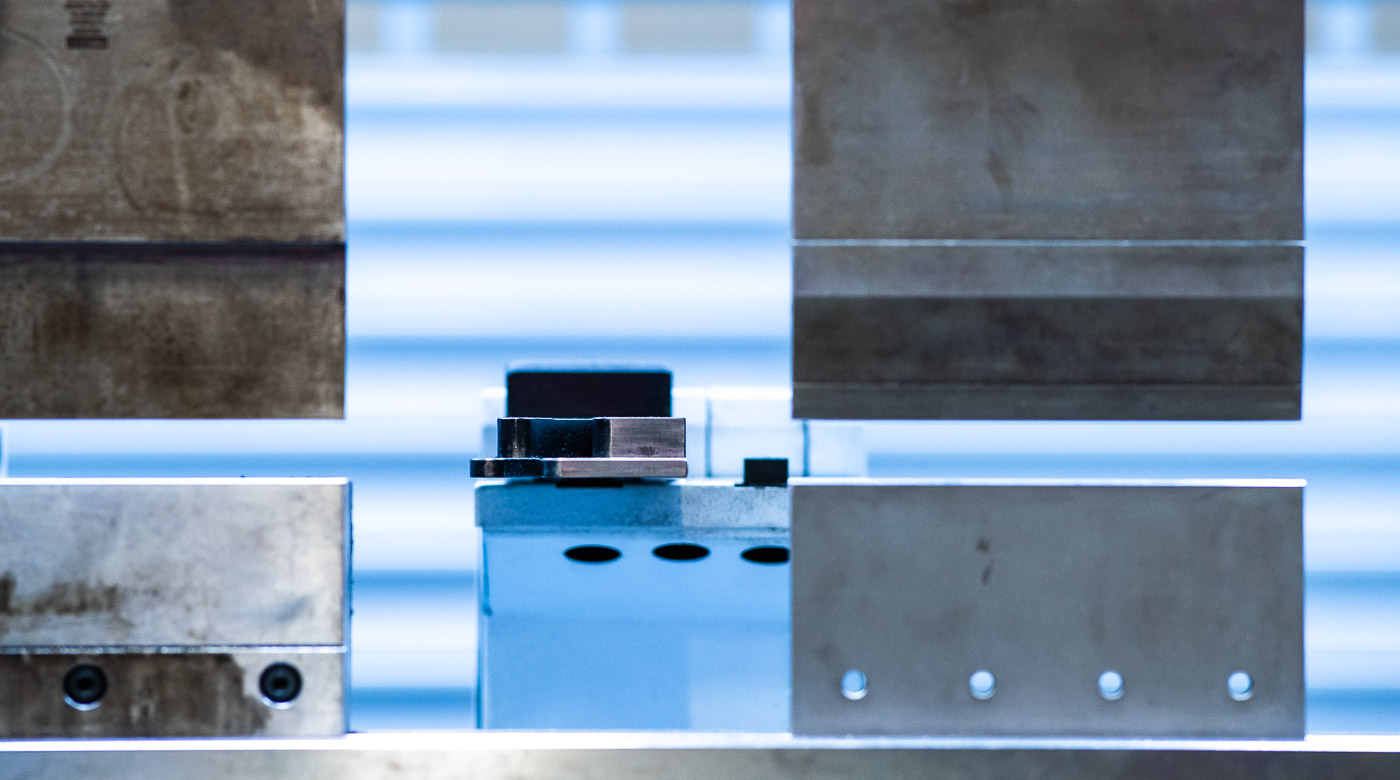

With us you will find bending, punching, laser cutting, sheet metal processing, welding, painting, prototype manufacturing, product

Our machine park for sheet metal consists of approximately 25 different machines across more than 8,000 square meters, including large

We process in most materials: cold rolled, hot rolled, copper, aluminum, stainless steel surface treated and other alloys. Thicknesses is

Due to today’s tough competition, every second can play a big role in the cost of a product. We help you with ideas for product adaptations

All HANZA factories hold a variety of certifications adapted to the business and technology in which they operate. The certificates complement our ambitious protocols for reduced environmental impact, data security, work environment and product quality.

ISO 9001 • ISO 14001 • ISO 45001

Switch number

+46 105 509 000

Visiting address

Svaneholms Bruk

SE-662 03 Svanskog

Address

Box 39

SE-670 10 Töcksfors

Sales Director

Veronica Svensson

+46 76 888 19 88

moc.aznah@nossnevs.acinorev

Account Manager

Reine Eriksson

+46 10 550 90 23

moc.aznah@nosskire.enier

Account Manager

Jimmy Olsson

+46 10 550 90 51

moc.aznah@nosslo.ymmij

Account Manager

Daniel Olsson

+46 76 000 41 10

moc.aznah@nosslo.leinad