Our production focuses on advanced series production of sheet metal constructions that effectively meet our customers’ needs. The size of our products varies from small to medium-sized, which can weigh up to 500 kg.

In Heinävesi, we manufacture sheet metal constructions by welding and machining. The factory also has a powder coating line,

The factory in Heinävesi covers an area of 6,500 square meters and provides a wide range of mechanical production. The company has about 30

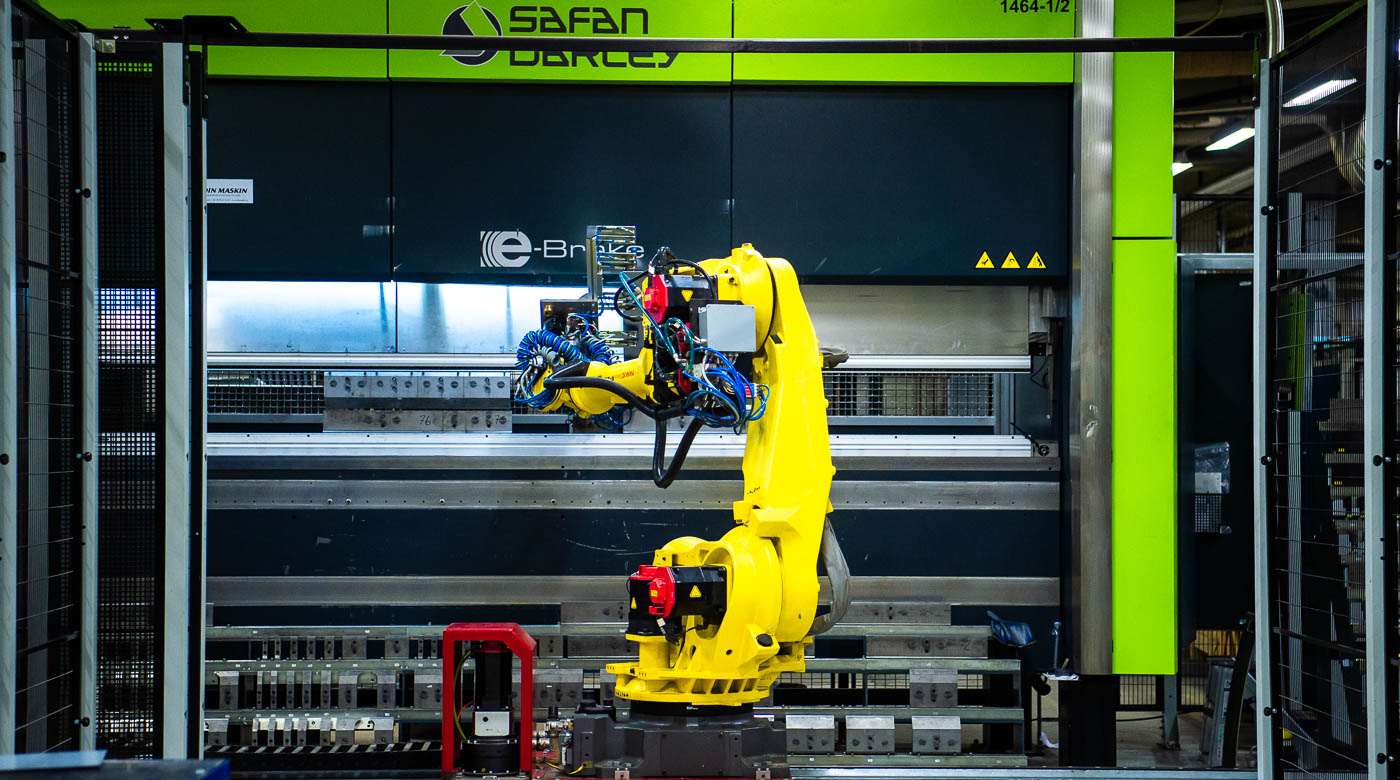

The factory provides a range of solutions customized to your needs: Laser cutting, punching, press brakes, welding,

Our various product packages are based on solid experience and high professionalism. Through the company’s long history,

All HANZA factories hold a variety of certifications adapted to the business and technology in which they operate. The certificates complement our ambitious protocols for reduced environmental impact, data security, work environment and product quality.

ISO 9001 • ISO 14001 • ISO 45001

Switch number

+358 405 51 52 55

Address

HANZA Mechanics Heinävesi

Ahjotie 3

FI-79700 Heinävesi

moc.aznah@isevanieh.sredro

Cluster President

Juhani Niiranen

+358 44 358 0971

moc.aznah@nenariin.inahuj

SCM Manager

Tuomo Pasanen

+358 40 745 6904

moc.aznah@nenasap.omout

Quality Manager

Sinikka Seppänen

+358 40 500 4700

moc.aznah@nenappes.akkinis