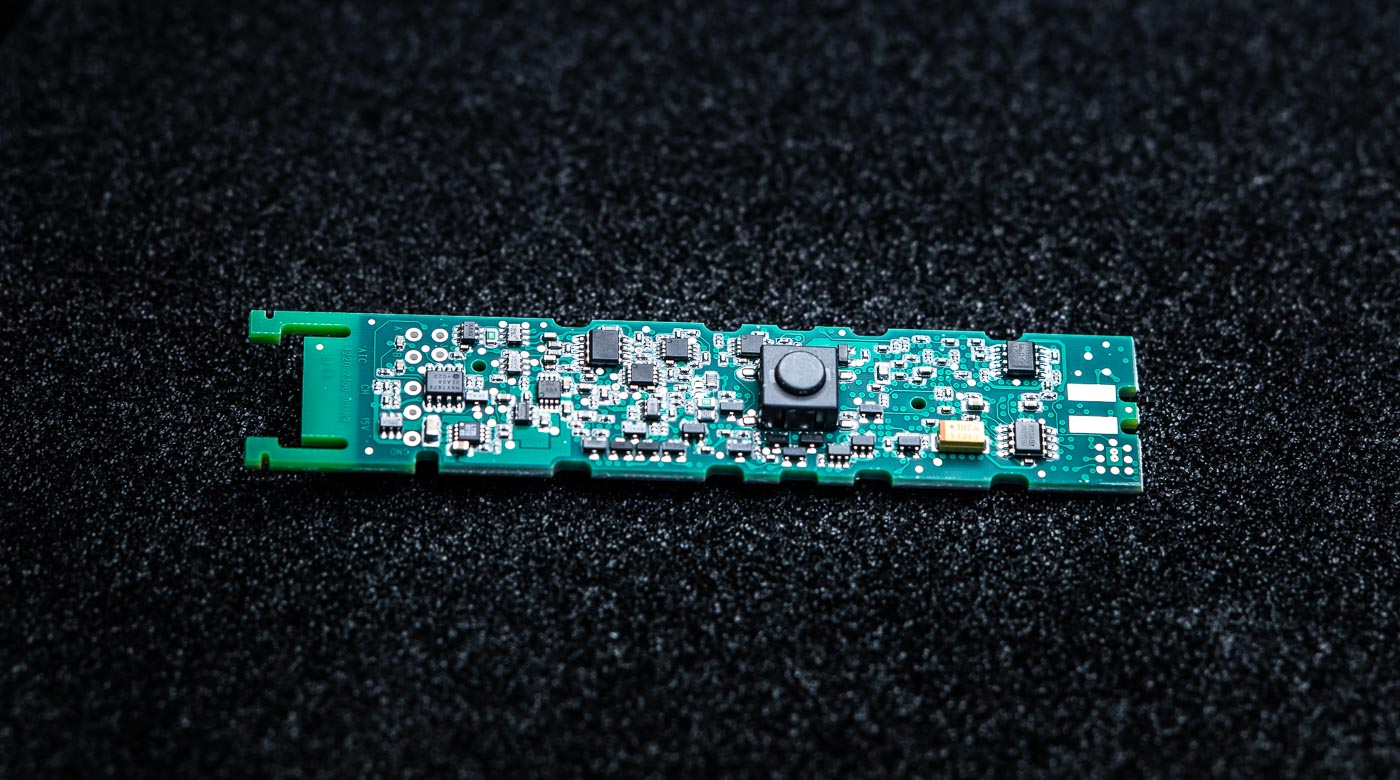

At HANZA Electronics Brzeg Dolny we offer complete electronics manufacturing services from PCBAs to complex boxbuild. We can handle everything from smaller project-based orders to high volume productions. We focus strongly on safety, quality and reliability.

Thanks to our committed employees and business partners, we can take care of the entire manufacturing and supply chain. Customers only have to

The electronics site in Poland was acquired as one of the first HANZA locations in 2008, the same year the company was founded.

We offer full technical support for our production processes. Together with the customer, we ensure that the product is designed in a way

We know that reliability and cost are two of the most important factors for our customers. Therefore, we ensure that our

All HANZA factories hold a variety of certifications adapted to the business and technology in which they operate. The certificates complement our ambitious protocols for reduced environmental impact, data security, work environment and product quality.

ISO 9001 • ISO 14001 • ISO 45001

Switch number

+48 603 755 288

Address

HANZA Electronics Brzeg Dolny

Aleje Jerozolimskie 38

56-120 Brzeg Dolny

Cluster President

Pawel Filarowski

+48 603 755 288

moc.aznah@iksworalif.lewap