HANZA Mechanics Tartu offers complete manufacturing solutions for various sectors, including medical equipment and appliances for food industry. In sheet metal production, we perform cutting, bending, punching, welding and powder coating. Our machining services include milling, turning, grinding, EMD and surface treatment. In cabling, we perform cutting, crimping, marking and assembly. We are able to assemble fully functional and tested products.

HANZA Mechanics Tartu specializes in various medium to high complexity items (low to medium volume) such as medical and food analyzers,

HANZA Mechanics Tartu has around 500 dedicated employees and 100 workcentres. In Tartu, Estonia, we operate from two locations

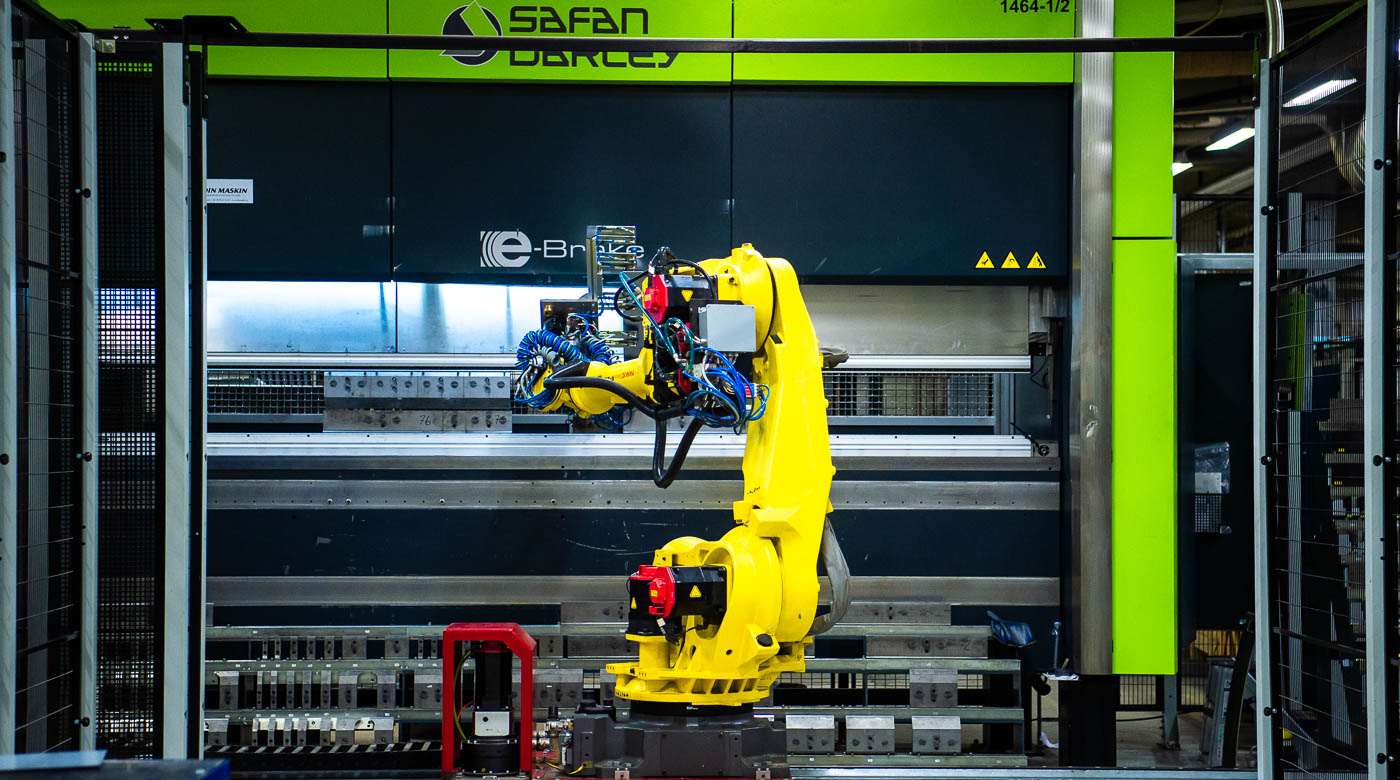

We have extensive experience and knowledge within sheet metal technology, punching, laser cutting, bending,

We have 110 years of experience in our field. We have deep knowledge in a variety of technologies and complex manufacturing processes.

All HANZA factories hold a variety of certifications adapted to the business and technology in which they operate. The certificates complement our ambitious protocols for reduced environmental impact, data security, work environment and product quality.

ISO 9001 • ISO 14001 • ISO 45001

ISO 3834-2

ISO 13485

Switch number

+372 746 88 00

Address

Silikaadi 5

EE-60534 Vahi village

Cluster President

Liivar Kongi

+372 562 426 33

moc.aznah@ignok.raviil