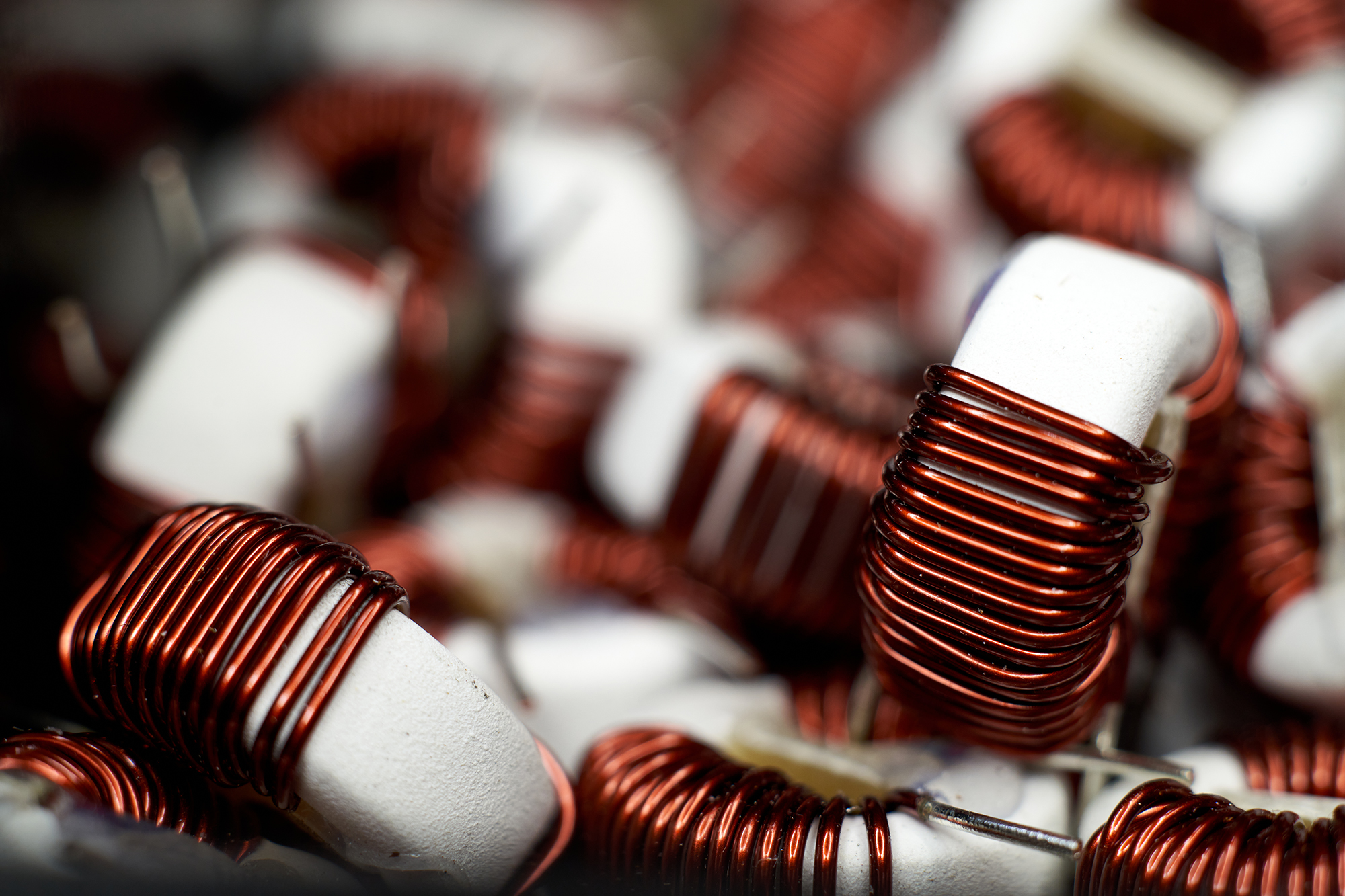

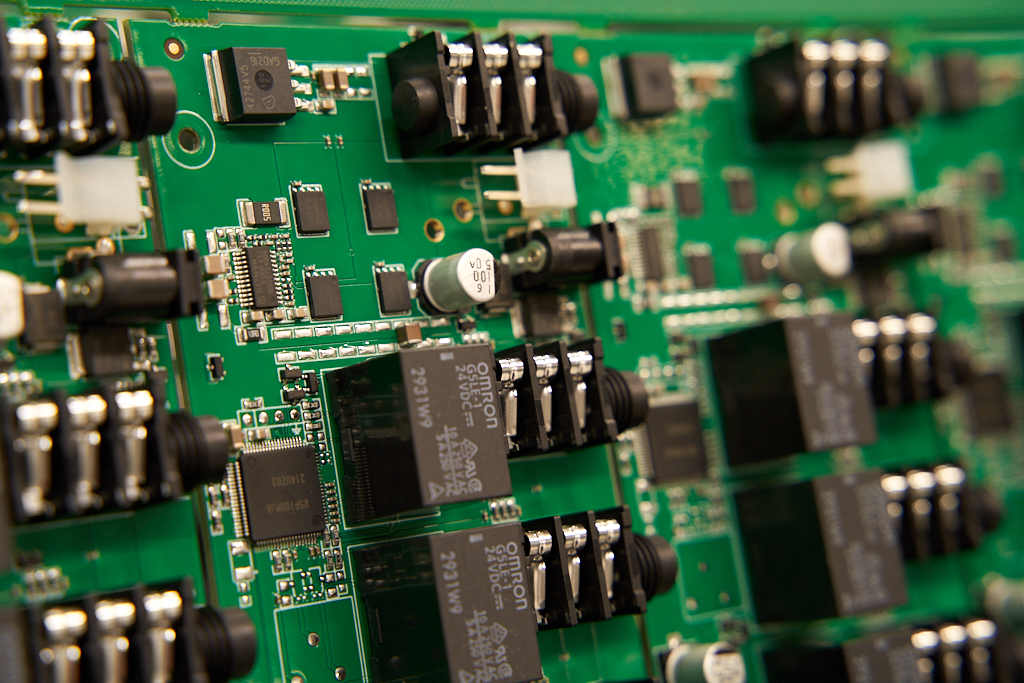

HANZA Electronics Ronneby is one of HANZA’s most modern electronics factories. At the site in Ronneby we offer highly automated electronics manufacturing in combination with box-build and logistic solutions to a wide variety of world-leading customers. We have long experience of tough requirements, specific classifications and manufacturing processes. Within HANZA Group we can also offer Test Development and Automation.

Here you will find everything from prototype production and test development to full-scale, highly automated series production. We also offer a well-developed and stable NPI process, complex assembly, and tailored logistics solution. Our strategic procurement department works globally within HANZA to benchmark suppliers and secure supply chains.

Our state-of-the-art machine park consists of three fully automatic SMT-lines including 3D AOI, 3D paste inspection and X-ray analysis. We also have two coating lines, two fully automatic selective soldering lines, two wave soldering machines, logistics areas and much more, spread over 12,500 square meters. Investments are made annually to offer the market’s most efficient processes.

Our everyday life includes tough requirements with specific classifications such as for medical equipment, but also products suited for partial or fully automated processes. With a high degree of automation and controlled manufacturing, we are definitely classified as one of the best in the market.

With today’s tough competition, we know that a tenth of a second can play a major role in the cost build-up of a volume product. We optimize and automate our processes for our customers products already from the start. What is normally manual production with others is often with us fully or partially automated. We have the opportunity for full traceability down to batch level on components but also processes throughout our production flow.

All HANZA factories hold a variety of certifications adapted to the business and technology in which they operate. The certificates complement our ambitious protocols for reduced environmental impact, data security, work environment and product quality.

ISO 9001 • ISO 14001 • ISO 13485

Switch number

+46 457 74200

Address

HANZA Electronics Ronneby

Fridhemsvägen 15

SE-372 38 Ronneby

Sales Director

Veronica Svensson

HANZA Group

+46 76 888 19 88

moc.aznah@nossnevs.acinorev

Site Manager

Kenneth Michaelsson

+46 70 965 10 64

moc.aznah@nossleahcim.htennek

Account Manager

Anna Johansson

+46 76 607 10 72

moc.aznah@nossnahoj.anna

Account Manager

Stefan Ohlsson

+46 70 965 10 96

moc.aznah@nosslho.nafets

Account Manager

Inger Lilja

+46 70 142 81 95

moc.aznah@ajlil.regni