HANZA Mechanics Narva provides manufacturing solutions in heavy mechanics. Our customers come from the mining, energy, material handling and mechanical engineering sectors. We also offer assembly services, which includes final assembly and testing of systems.

We specialize in complete and partial solutions in heavy mechanics. From welded chassis, frames and tanks to functional mining equipment

At HANZA Mechanics Narva, approximately 230 motivated employees work in a production area of 18,000 square meters. The factory has over

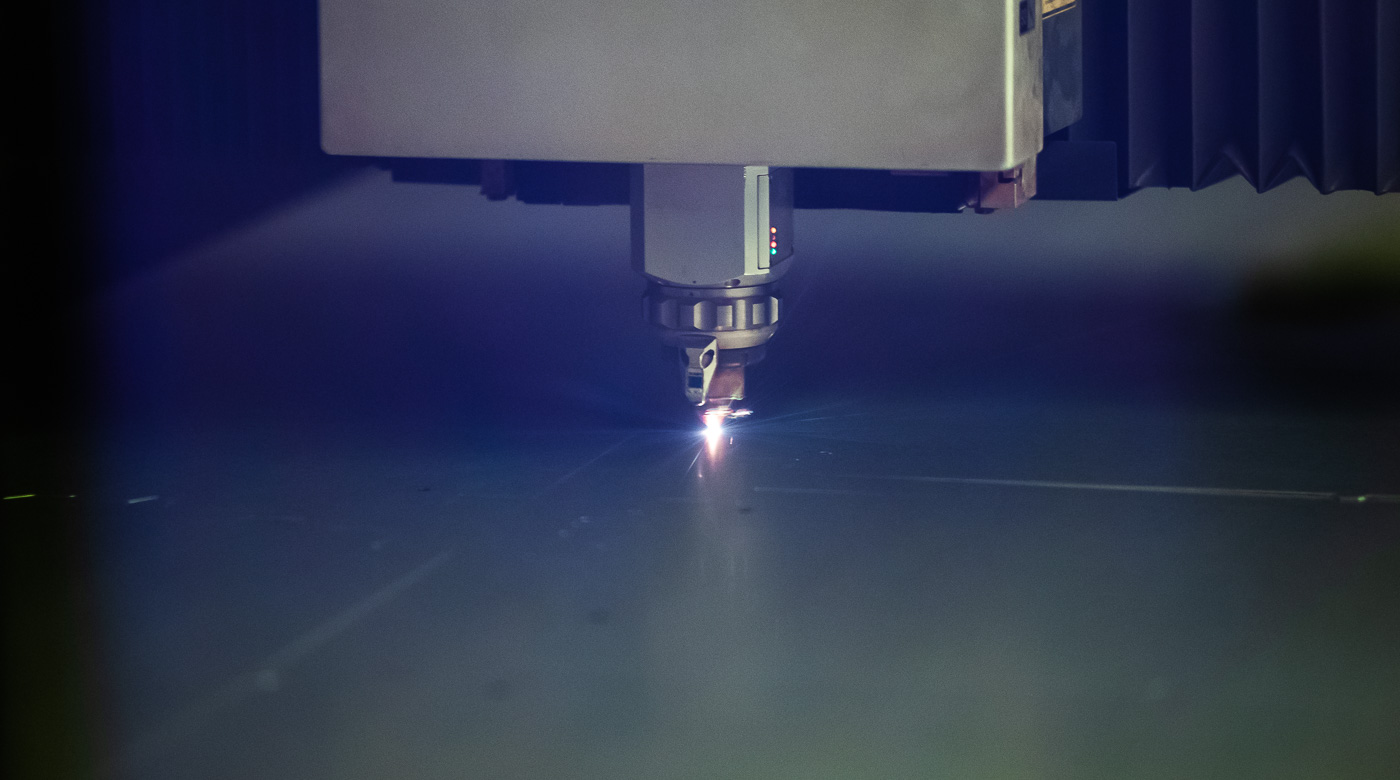

HANZA Mechanics Narva is fully equipped to operate in heavy mechanics: thick sheet metal (over 6mm), welding (robot and manual),

Our complete solution in heavy mechanics means that we have full capacity to both manufacture and offer final assembly of steel components

All HANZA factories hold a variety of certifications adapted to the business and technology in which they operate. The certificates complement our ambitious protocols for reduced environmental impact, data security, work environment and product quality.

ISO 9001 • ISO 14001 • ISO 45001

ISO 3834-2

Switch number

+372 746 88 00

Address

Kulgu 5

EE-20104 Narva

Cluster President

Liivar Kongi

+372 562 426 33

moc.aznah@ignok.raviil