HANZA Electronics Årjäng is one of HANZA’s most modern electronics factories with IPC class 3 production. At the site in Årjäng we offer highly automated electronics manufacturing in combination with box-build and logistic solutions to a wide variety of world-leading customers. Here you’ll also find HANZA Group Test Development and Automation center, with long experience of tough requirements, specific classifications and manufacturing processes.

Here you will find everything from prototype production and test development to full-scale, highly automated series production. We also offer

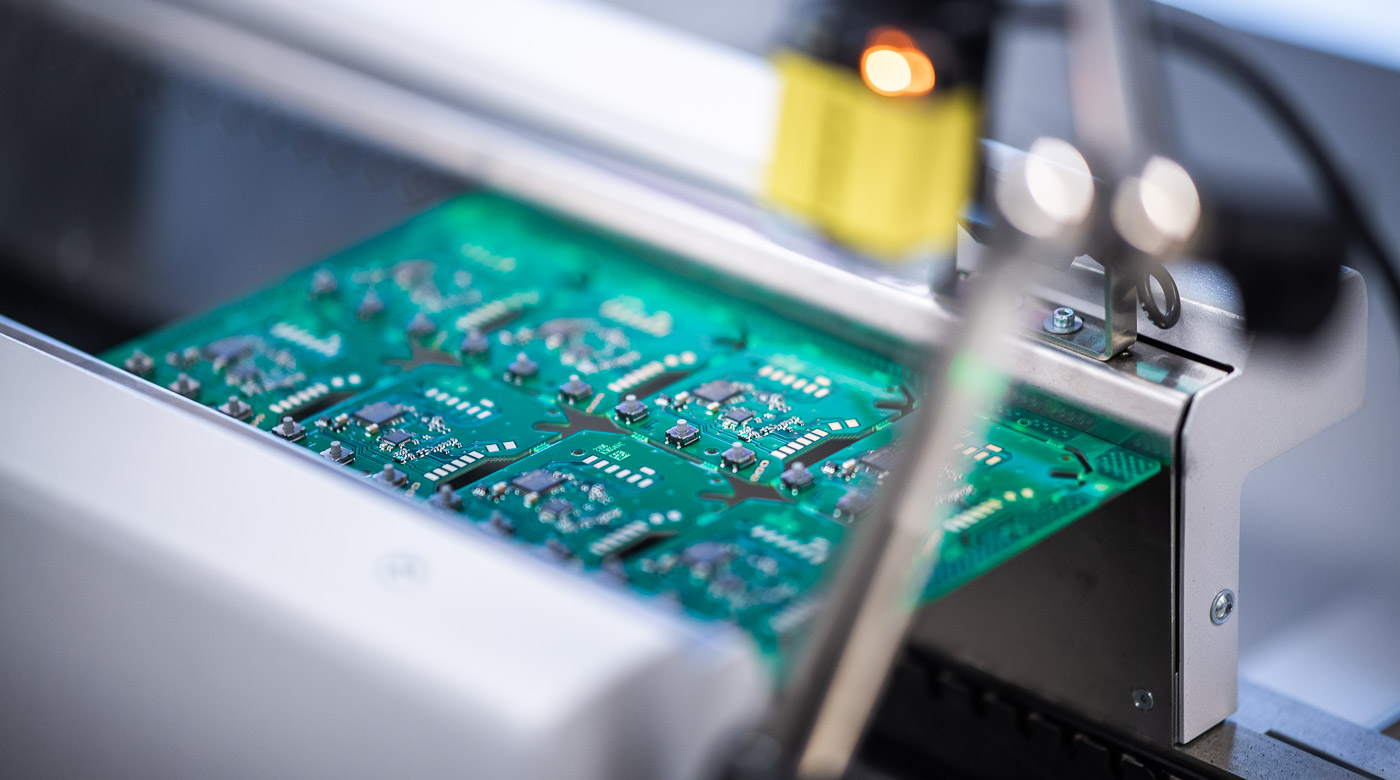

Our state-of-the-art machine park consists of two fully automatic SMT-lines including 3D AOI, 3D paste inspection

Our everyday life includes tough requirements with specific classifications. From military-grade manufacturing to medical equipment and IPC class 3 production,

With today’s tough competition, we know that a tenth of a second can play a major role in the cost build-up of a volume product. We optimize

All HANZA factories hold a variety of certifications adapted to the business and technology in which they operate. The certificates complement our ambitious protocols for reduced environmental impact, data security, work environment and product quality.

ISO 9001 • ISO 14001 • ISO 45001

ISO/IEC 27001

Switch number

+46 573 14300

Address

HANZA Electronics Årjäng

Brännaregatan 3

Box 904, 672 29 Årjäng

Sales Director

Veronica Svensson

HANZA Group

+46 76 888 19 88

moc.aznah@nossnevs.acinorev

Site Manager/Account Manager

Peter Väisänen

+46 70 318 52 71

moc.aznah@nenasiav.retep

Account Manager

Ove Olsson

+46 70 551 04 63

moc.aznah@nosslo.evo

Account Manager

Niklas Björklund

+46 76 795 31 47

moc.aznah@dnulkrojb.salkin